You can predict more and react less with boiler management from IntelliSense™ powered by Ackumen™.

You know the story. Boiler operators are constantly battling issues that plague their boiler system processes. Scaling and corrosion. Pretreatment and boiler inefficiencies. High fuel, chemical, and repair costs. Decreased equipment life. And unscheduled downtime. But did you know that you can predict and minimize those problems? At every stage—from pretreatment to boiler to condensate?

What if you could be confident you’re getting optimal

- Performance from your softener, and insights into that performance

- Regeneration from your softener tank, based on 24/7 monitoring

- Results from your deaeration system

- Monitoring of your stack gas temperature

- Treatment of condensate before it goes to the feedwater

You can. With boiler management from IntelliSense powered by Ackumen.

Get insights to help you succeed.

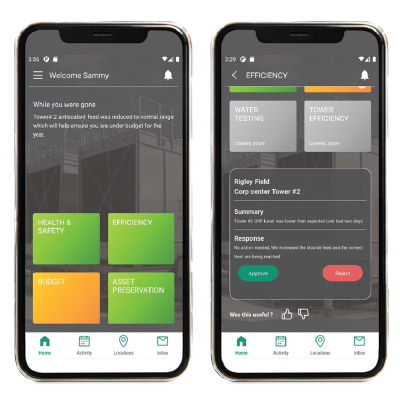

The Ackumen platform uses cloud-based data to deliver important insights right to your mobile device or desktop. You’ll get easy-to-read, actionable system graphics that show you how process indicators are behaving. You’ll also get alarms and notifications. And with just a glance, you’ll know whether an action is recommended now or later.

Manage chemistry better.

SMART Inventory is our automatic inventory control system. It uses IoT sensors to monitor chemical supply in any container. You’ll get 24/7 inventory insights delivered directly to your mobile device. You’ll also get usage-based alerts. One-click ordering. And more. Managing your chemistry has never been more efficient.

Let boiler management from IntelliSense powered by Ackumen help make you the hero.

Simplify how you manage your low-pressure boiler system and be more proactive than reactive. You’ll increase process efficiencies from start to end. Protect equipment. Cut costs. And create a safer working environment. Connect with one of our Digital Water specialists today.

Please reach out with any questions about your system or to request a free site survey.